Qingdao Quanrongxin Packaging Co., Ltd

Good faith for the purpose of quality for customer satisfaction

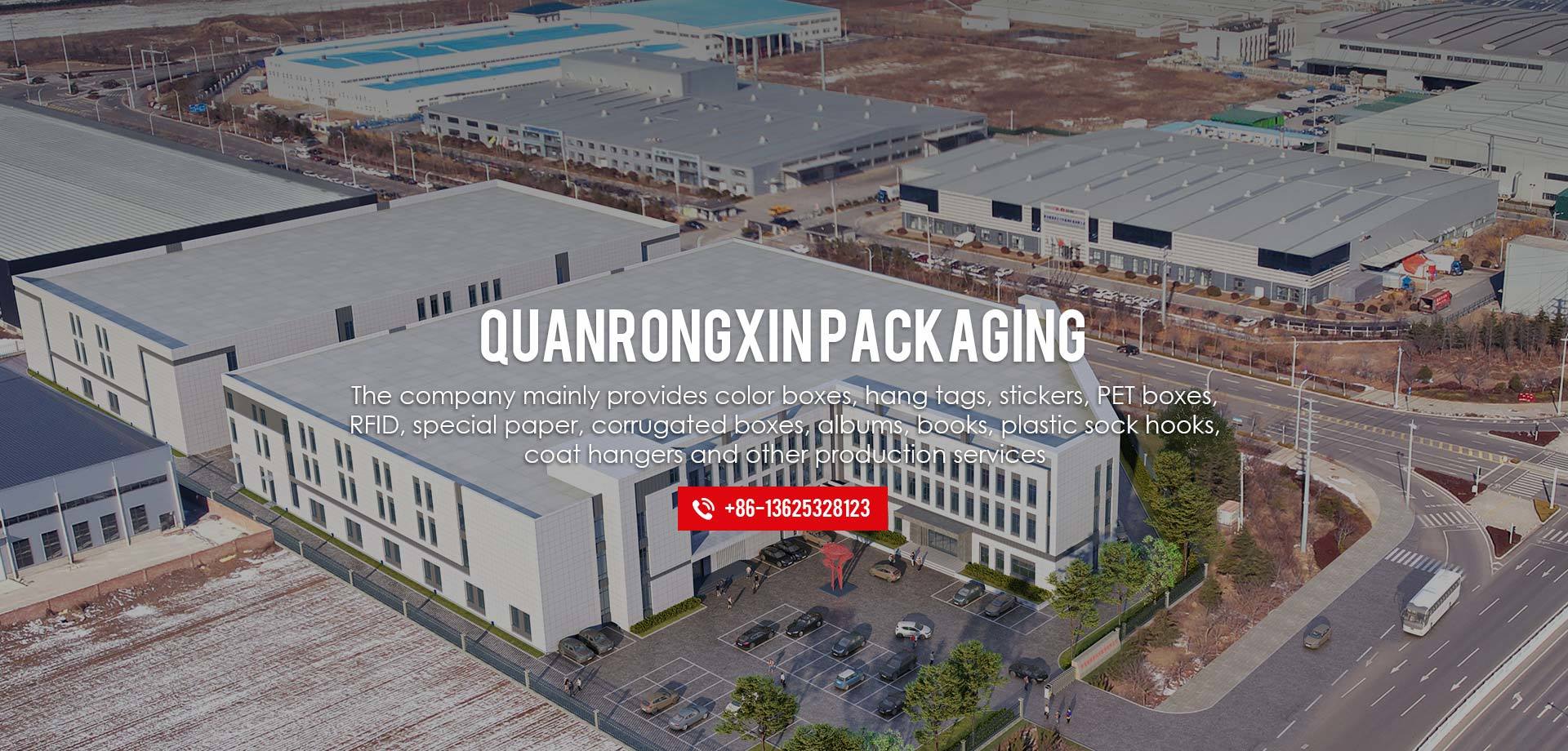

Qingdao Quanrongxin Packaging Co., Ltd. is a private enterprise with independent legal personality. The company was founded in 2002 and is now located in the new city of automobile industry in Jimo District, Qingdao City, with superior geographical location and convenient transportation. Company plant area of 40000 square meters, is a set design, packaging, printing in one of the modern integrated packaging and printing production enterprises.

Over the years, the company has been deeply engaged in the field of medium and high-end packaging and printing. Its products cover color boxes, tags, stickers, PET boxes, RFID, special paper, corrugated boxes, picture albums, books and periodicals, plastic socks hooks, hangers and other aspects. It is committed to providing customers with integrated services for medium and high-end packaging and printing products.

Company establishment

Company plant area

Equal price, quality wins, equal quality, price wins

PRODUCT

EQUIPMENT

The company has advanced offset printing, digital printing, label printing, RFID and other production lines and supporting production equipment, which can fully meet the personalized, diversified and large-scale production needs of customers.

UV printing machine

UV printing machine

Printing machine

RFID Equipment

Fuji Xerox Digital Printing Machine

Belgium Saikang 3050 Digital Printing Machine

Lindeko Label Printing Machine

Automatic laminating machine

Automatic die-cutting hot stamping machine

Full-automatic die-cutting machine

Automatic inspection machine

Automatic inspection machine

OUR SERVICES

Over the years, the company has continuously optimized the whole life cycle service of products, adhering to the concept of "products have delivery time and endless service", and has arranged special personnel to follow up the service for all customers, so as to handle the customer's order requirements efficiently and professionally. For all orders, independent sample cards are established to ensure the accuracy of order information and product information. For all products, special standard books are made to ensure the quality of products; for all products delivered to customers, they are delivered in strict accordance with the prescribed delivery date, and do a good job of inventory management, and strive to provide customers with the whole chain, the whole link, the whole cycle of intimate service.

-

DESIGN

There are a number of high-quality senior professional designers and skilled printing technicians, so that the company has a strong market competitiveness.了解更多 + -

PRINT

The company has the industry's most advanced offset printing, digital printing, label printing, RFID and other types of production lines and supporting production equipment, to fully meet the customer's personalized, diversified, large-scale production needs.了解更多 + -

PACKAGING

The company firmly believes that only with better equipment can we produce better products, and vigorously introduce production equipment to create a higher level of production lines and production processes in the industry.了解更多 + -

SERVICE

For pre-press design, production and printing, post-quality control, distribution and delivery, layers of control, layers of screening, whether it is the quality, cost, aesthetics, details will be your more worry, more assured, more trustworthy choice.了解更多 +

Qingdao Quanrongxin Packaging Information

12-19

Paper packaging printing process

There are many paper packaging and printing processes. The following is an introduction to several commonly used printing processes: bronzing process The expression of bronzing process is to make the required bronzing or silver stamping pattern into relief plate heating, then place aluminum foil of the required color on the printed matter, and after pressure, make the aluminum foil adhere to the printed matter.

12-19

Paper packaging printing technology presents new features

The application of modern technology in the field of packaging and printing has simplified many packaging and printing processes and made them more scientific and reasonable. For example, in the past, the extrusion, hot pressing, stamping and other molding processes of plastic packaging have been gradually used in the molding of cardboard packaging, so that products that could not be packaged with paper in the past have also been packaged with paper. As a result, the paper packaging printing technology has also changed.

05-13

New trends in printing-the momentum of water-based inks

The first high-end prepress production system based on PDF; Dot technology dedicated to flexographic printing; Polar cutting system using CIP3 workflow; Offset printing rotary machine; The first process system to successfully use laser technology to engrave gravure cylinders; Professional digital photography technology; New drying technology (online one-time formation); New technology for printing pressure-sensitive internal labels; Software package (prepress system); Scanning software system; printing systems for the print-on-demand market.